Guides

How to Use a Liquid Ring Vacuum Pump

Liquid ring pumps are important machines used in various applications in many industries. These industries include sugar, paper, seawater deaeration, distilleries, pharmaceutical, asbestos manufacturing and even the textile industry, among others. These pumps operate better than other kind of pump because of their varied uses. They not only condensate vapors, but can also use various kinds of fluids while maintaining the performance at an optimal level. You can find a variety of these pumps from Vooner by just clicking this link https://www.vooner.com/liquid-ring-vacuum-pumps/. You, however, need to know how to use these pumps to get the best out of them. Here are a few pointers on how to do so.

A typical liquid ring vacuum pump consists of the rotor impeller, a shaft, a liquid ring, impeller blades, and inlet and discharge ports. The impeller and liquid sealant create a vacuum inside the housing. The impeller rotates in an eccentric casing that allows the liquid water in most cases to almost fill and almost empty the rotor chambers in one revolution. The liquid moves back to the center of the impeller. This movement creates a compression allowing for the pumping action to take place. The gas escapes via the discharge ports to the atmosphere. The exhaust fumes discharged are replaced by a constant flow of cool seal liquid to repeat the entire process.

Now that you know the basic principles behind the operation of a liquid ring vacuum pump, you must understand how to handle this machine to ensure you do not mess up with it. Once you get the pump, avoid the temptation of test running the machine. Take it through the installation process and fill it with the sealing liquid. Only then can you run it and keep watch for the first few hours.

You should place this pump on a stable platform like on a floor, or get a stable pallet. The pumps run smoothly, but the vibrations can move them. If placed on an unstable surface, it might interfere with their normal functioning like filling up the rotor chambers more than it is required. If the chambers fail to fill or empty as required, the gasses are not going to be compressed and hence interfere with the normal pump system.

When fixing the pipes, inspect them carefully to avoid stresses. Check the joints too, and ensure that they are also free from stress. These pipes and joints can develop stresses while in transit. If you fix them immediately after offloading, you might end up messing the entire pump system. The pumps are costly, and repairing them is not cheap either. So, be careful and patient when doing the installation.

There are those pumps that use V-belts. These belts will require you to set the tension on the belt drive, but you first need to install and align the sheaves. You can then fix the belt into the grooves while placed on the sheaves. Ensure that you check the sheaves and the belts’ tension after every few days to ensure the normal functioning of the pump. Stay keen for any odd noises from the belts. If you hear some squealing noises, then you need to adjust the tension. There are times when you need to shut down the pump for maintenance to just let the pump rest. When shutting the pump for a few days. Release the tension from those belts.

Vacuum pumps are vulnerable to extreme temperature conditions. You should not operate your pump in a freezing environment, as that will free the sealant liquid and mess up with the system. If the temperature is also too high, it will wear out the rubber from the belts causing them to lose their tension. The vacuum operates effectively at moderate temperatures and in a non-humid environment. Avoid coating the sheaves with lubricants like oil as it reduces the quality of rubber belts. You should also use the same type of belts instead of mixing a variety for the best performance.

You should ensure that there is a consistent supply of water all the time when the pump is running. Ensure that you connect the pipes bringing in the water properly to the inlet port, and check for any blockages and dirt. These pipes need to be as clean as possible, otherwise, any debris might mess up the rotating impeller blades.

Last but not least, always make sure you place the pump near a power supply to avoid the risk of unknowingly plugging off the pump. Check the power requirements before plugging in and running the pump.

Guides

What is DoujinDesu? & Top 10 Alternatives for Manga Lovers in 2024

DoujinDesu is an online platform that caters to anime and manga enthusiasts, specifically focusing on doujinshi—self-published works created by independent artists. The site serves as a hub for fans to explore a diverse range of manga, novels, and art, fostering a community-driven experience. Users can easily access a vast library of content, enabling them to discover new artists and stories while supporting independent creators. However, the legality of content shared on DoujinDesu has raised concerns among users, prompting many to seek alternatives.

Legal Considerations for Manga Lovers

When accessing manga online, it’s essential to consider legal implications. Doujinshi often exists in a gray area regarding copyright laws, as many works may not have official licenses. While platforms like DoujinDesu provide a space for independent creators, users should be aware of the potential legal risks involved in accessing and sharing unlicensed content. To navigate these concerns, many manga lovers opt for platforms that offer officially licensed material, ensuring a legal and ethical reading experience.

How to Fix Left 4 Dead 2 Install Problems, Freezes and Errors

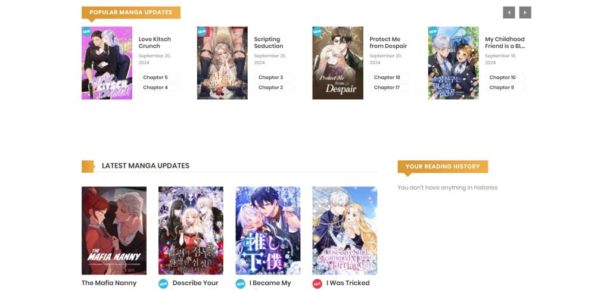

Top 10 Alternatives to DoujinDesu in 2024

Here are ten noteworthy alternatives for manga lovers looking for safe and legal content:

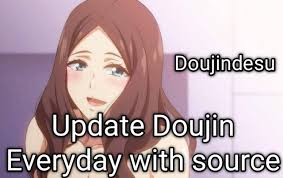

1. Manganato

Manganato offers a large collection of manga across various genres, making it a popular choice for readers. The user-friendly interface allows for easy navigation and access to the latest chapters.

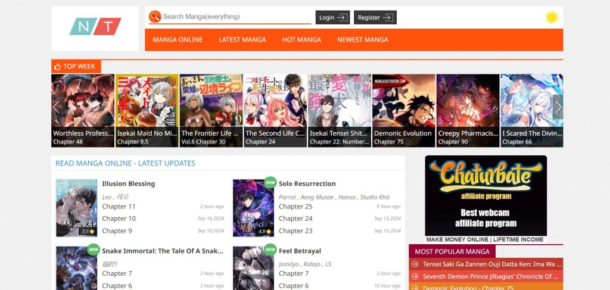

2. MangaDex

MangaDex is a well-established platform that focuses on community-driven content. It hosts a wide array of manga, allowing users to upload their translations and enjoy a diverse selection of titles.

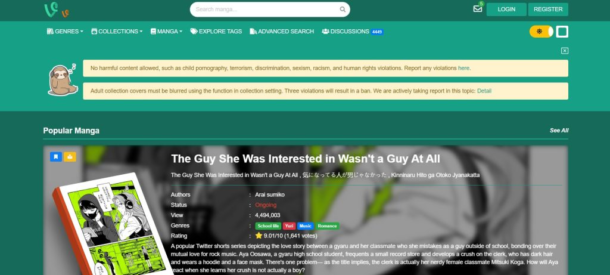

3. VyManga

VyManga provides an extensive library of manga titles, with a particular focus on user-friendliness and accessibility. The site is frequently updated with new releases and popular series.

4. CoffeeManga

CoffeeManga caters to fans looking for high-quality manga with a clean interface. It features a range of genres and allows users to browse easily and discover new content.

5. Manganelo

Manganelo is another excellent alternative that offers a vast collection of manga. The site features an intuitive layout, making it simple for users to find their favorite series and explore new ones.

Escape Room Game Answers: Find All Level Answers at a Single Place

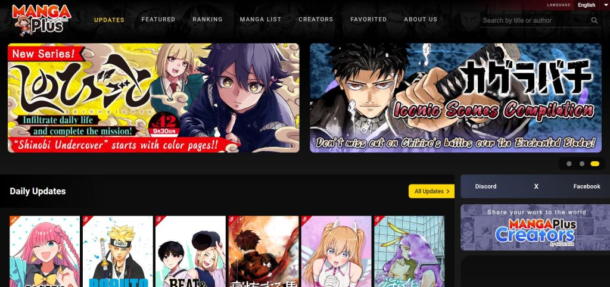

6. Manga Plus

Manga Plus is an official platform by Shueisha, providing access to popular manga titles as they are released in Japan. Users can read many series for free, making it a legal and ethical option.

7. KunManga

KunManga focuses on providing a wide variety of manga titles, featuring both popular series and lesser-known gems. The site emphasizes user engagement, allowing readers to leave comments and recommendations.

8. Webtoon

Webtoon is a popular platform that specializes in webcomics and digital manga. With a diverse range of genres and original content, it caters to a broad audience of readers.

The 5 Most Popular eSports Games in Japan

9. MangaPlaza

MangaPlaza offers a rich library of manga, focusing on providing officially licensed content. The platform features user-friendly navigation and a variety of genres.

10. MangaBerri

MangaBerri is known for its vast collection of manga, with a straightforward interface that makes finding and reading series easy. The platform often updates its library with new releases.

How to Choose the Best Manga Platform for You?

Selecting the right manga platform depends on several factors, including your reading preferences, the availability of titles, and legal considerations. Consider the following when making your choice:

- Content Variety: Look for platforms that offer a wide selection of genres and titles.

- Legal Status: Prioritize platforms that provide officially licensed content to ensure a legal reading experience.

- User Experience: Evaluate the site’s layout and ease of navigation.

- Community Engagement: Some platforms encourage user interaction and reviews, enhancing your reading experience.

Why DoujinDesu Alternatives Matter?

Finding alternatives to DoujinDesu is essential for manga lovers who wish to access content safely and legally. By exploring other platforms, readers can discover a broader range of officially licensed titles, support artists and creators, and engage with vibrant online communities. The shift towards legal platforms also helps to combat piracy and promotes the growth of the manga industry.

Conclusion

DoujinDesu has captured the hearts of many anime and manga fans, but its legal implications have led many to seek alternatives. Fortunately, a wealth of platforms exists to cater to manga lovers’ diverse tastes and preferences. By exploring these alternatives, readers can enjoy a legal, enriching experience while supporting the creators they admire.

Frequently Asked Questions (FAQs)

What makes DoujinDesu popular?

DoujinDesu is popular due to its extensive collection of doujinshi, user-friendly interface, and strong community engagement, allowing fans to discover new artists and stories.

Are there legal issues with DoujinDesu?

Yes, DoujinDesu operates in a gray area concerning copyright laws, as many doujinshi may not have official licenses. Users should be aware of potential legal risks when accessing the platform.

What are the best free alternatives to DoujinDesu?

Some of the best free alternatives include Manganato, MangaDex, and Webtoon, which offer a wide selection of manga and webcomics without legal issues.

How can I safely access manga online?

To safely access manga online, choose platforms that provide officially licensed content and prioritize user safety and copyright compliance.

Which manga platforms are recommended for the UK audience?

Platforms like Manga Plus and Webtoon are highly recommended for the UK audience, as they offer a range of officially licensed content and cater to international readers.

How does DoujinDesu compare to MangaDex?

While DoujinDesu focuses on doujinshi, MangaDex provides a more extensive library of community-driven translations, allowing users to explore a wider variety of titles.

Can I find rare manga on these platforms?

Yes, many of the alternative platforms mentioned, such as MangaDex and KunManga, may feature rare or lesser-known titles, making them great resources for manga enthusiasts.

Guides

Is Stake.us Legal in the US? What States Can You Play Stake.us In?

Stake.us is a sweepstakes-based social casino that allows U.S. players to enjoy casino-style games for free. Unlike Stake.com, which operates globally with real-money gaming, Stake.us is designed specifically for U.S. players. It uses a sweepstakes model that complies with U.S. regulations, offering players the chance to win real prizes using virtual currency (Stake Cash and Gold Coins). This article provides a comprehensive overview of Stake.us’s legal status and the states where it is accessible.

Understanding the Legality of Stake.us in the U.S.

Online gambling in the U.S. is governed by a complex set of laws, varying between federal and state levels. The federal Unlawful Internet Gambling Enforcement Act (UIGEA) impacts online gambling, but sweepstakes casinos like Stake.us operate legally under different frameworks. By offering virtual currency instead of real-money gambling, Stake.us complies with the laws in most U.S. states.

Stake.us uses two forms of virtual currency:

- Gold Coins: Used for entertainment and have no monetary value.

- Stake Cash: Can be redeemed for sweepstakes prizes after meeting certain conditions.

This model allows Stake.us to operate legally across most of the U.S. and makes it accessible to a wide range of players.

States Where Stake.us is Legal

As of 2024, Stake.us is legal and accessible in 43 U.S. states, making it one of the most widely available social casinos in the country. Some of the key states where Stake.us is legal include:

- California

- Texas

- Florida

- Ohio

- Pennsylvania

- New Jersey

Players in these states can freely register and participate in sweepstakes-style casino games. Popular games on the platform include Stake Originals, slots, and table games, with promotions offering bonuses like free Gold Coins and Stake Cash for new users.

States Where Stake.us is Restricted

Despite its wide availability, Stake.us is restricted in seven U.S. states due to local regulations that prohibit online gambling or sweepstakes-based gaming. The states where Stake.us is not available are:

- New York

- Washington

- Nevada

- Idaho

- Kentucky

- Michigan

- Vermont

In these states, sweepstakes casinos are treated similarly to traditional online gambling, making Stake.us inaccessible to residents. The legal restrictions vary from state to state but are often based on long-standing gambling laws.

Why is Stake.us Legal in Most States?

Stake.us operates within the boundaries of U.S. gambling laws by offering virtual, non-monetary prizes. Players earn Gold Coins through regular play or by purchasing them. In the case of purchases, Stake.us provides bonus Stake Cash, which can be redeemed for real-world prizes once users meet specific criteria. This distinction from real-money gambling allows Stake.us to navigate strict gambling regulations and remain compliant in most states.

How to Play Stake.us Safely and Legally

To enjoy Stake.us, players should always verify the platform’s availability in their state. Registration is easy and often comes with welcome bonuses, like free Stake Cash and Gold Coins for new users. For safe and responsible play, Stake.us also offers various tools to limit gaming activity and promote responsible gambling behavior.

FAQs on Stake.us Legality

- Is Stake.us legal in the U.S.?

Yes, Stake.us operates legally in most U.S. states through its sweepstakes casino model. - Can I play Stake.us in New York?

No, Stake.us is restricted in New York, along with six other states due to local regulations. - What’s the difference between Stake.us and Stake Casino?

Stake.us is a sweepstakes-based social casino for U.S. players, while Stake Casino offers real-money gaming globally.

Conclusion

Stake.us provides U.S. players a legal way to enjoy casino-style games in 43 states, operating under the sweepstakes model that aligns with U.S. regulations. Players should always check their state’s gambling laws before registering and take advantage of the bonuses and free-play features available. While Stake.us is restricted in a few states, it remains a popular and accessible option for millions of players across the country.

Guides

How Old Is Gekko Valorant? Age Details Of Agent Revealed

Gekko has captured the interest of the Valorant community. Gekko has grown to be a fan favorite thanks to his easygoing demeanor and formidable fighting abilities. However, how old is this fascinating agent exactly?

Key Takeaways

- Riot Games has not officially revealed Gekko’s age, leaving fans to speculate based on his behavior and style.

- Gekko’s youthful energy, use of contemporary slang, and laid-back attitude suggest he is likely in his late teens or early twenties.

- His interactions with older agents imply he sees himself as younger or less experienced than some of the veterans in the game.

- Gekko’s fashion sense and the voice actor’s youthful portrayal align with the image of a younger character appealing to a modern audience.

Gekko’s Introduction To Valorant

Gekko was introduced as part of Valorant’s varied roster of agents, all from different corners of the world. His history shows that he is a Los Angeles native of Mexican-American descent, adding a distinct ethnic flavor to the game.

Gekko’s talents stem from his relationship with his pets, whom he affectionately calls “his buddies.” This unique relationship enables him to execute a variety of tasks, from reconnaissance to area denial, making him a versatile agent on the battlefield.

Discover how to save more on gaming with our 9 Money-Saving Tips Every Gamer Needs to Know.

Speculations About Gekko’s Age

Valorant agents’ ages are frequently unknown, with Riot Games only giving hints about their backstories and ages on rare occasions. Riot has not revealed Gekko’s exact age, enabling fans to conjecture based on his appearance, demeanor, and voice lines.

Gekko is frequently described as youthful and lively, with a style that appeals to a younger audience. His voice lines and interactions with other agents indicate a lighthearted and upbeat demeanor, which is normally associated with someone in their late teens or early twenties. His fashion sense, which combines streetwear and casual attire, mirrors contemporary trends among younger generations.

Contextual Clues From The Game

While Gekko’s actual age remains unknown, surrounding evidence provides insight into his likely age range. For example, the voice actor, who was chosen to bring Gekko to life, is relatively young, implying that Gekko is meant to be a youthful figure. Gekko’s laid-back attitude, mixed with his close bond with his critters, evokes a sense of young wonder and adventure.

Gekko’s interactions with the other agents in Valorant also include subtle indications. He frequently alludes to senior agents with a mix of respect and lighthearted irreverence, which may indicate that he considers himself younger or less experienced than veterans such as Brimstone or Sage.

His English is rife with contemporary slang, confirming the notion that he is a member of the younger generation.

Learn the secrets to success with our Fantasy Sports Hacks for Building a Winning Team.

Conclusion

While Riot Games has yet to confirm Gekko’s actual age, hints in his character design, voice lines, and interactions with other agents strongly suggest that he is in his late teens or early twenties. His youthful energy, modern fashion style, and upbeat attitude on life make him a relatable figure to many players.

-

Guides5 years ago

Guides5 years ago6 Proven Ways to Get more Instagram Likes on your Business Account

-

Mainstream10 years ago

Mainstream10 years agoBioWare: Mass Effect 4 to Benefit From Dropping Last-Gen, Will Not Share Template With Dragon Age: Inquisition

-

Casual11 months ago

Casual11 months ago8 Ways to Fix Over-Extrusion and Under-Extrusion in 3D Printing

-

Mainstream12 years ago

Mainstream12 years agoGuild Wars 2: The eSports Dream and the sPvP Tragedy

-

Guides8 months ago

Guides8 months agoExplore 15 Most Popular Poki Games

-

Mainstream6 years ago

Mainstream6 years agoHow to Buy Property & Safe Houses in GTA 5 (Grand Theft Auto 5)

-

Uncategorized4 years ago

Uncategorized4 years agoTips To Compose a Technical Essay

-

iOS Games1 year ago

iOS Games1 year agoThe Benefits of Mobile Apps for Gaming: How They Enhance the Gaming Experience